Spot UV printing is popular in the printing and packaging processes because it affects the final look of packages. However, does it worth using this technique to create quality packaging? It is beneficial if you know about this technique and its process.

What Does a Spot UV Mean?

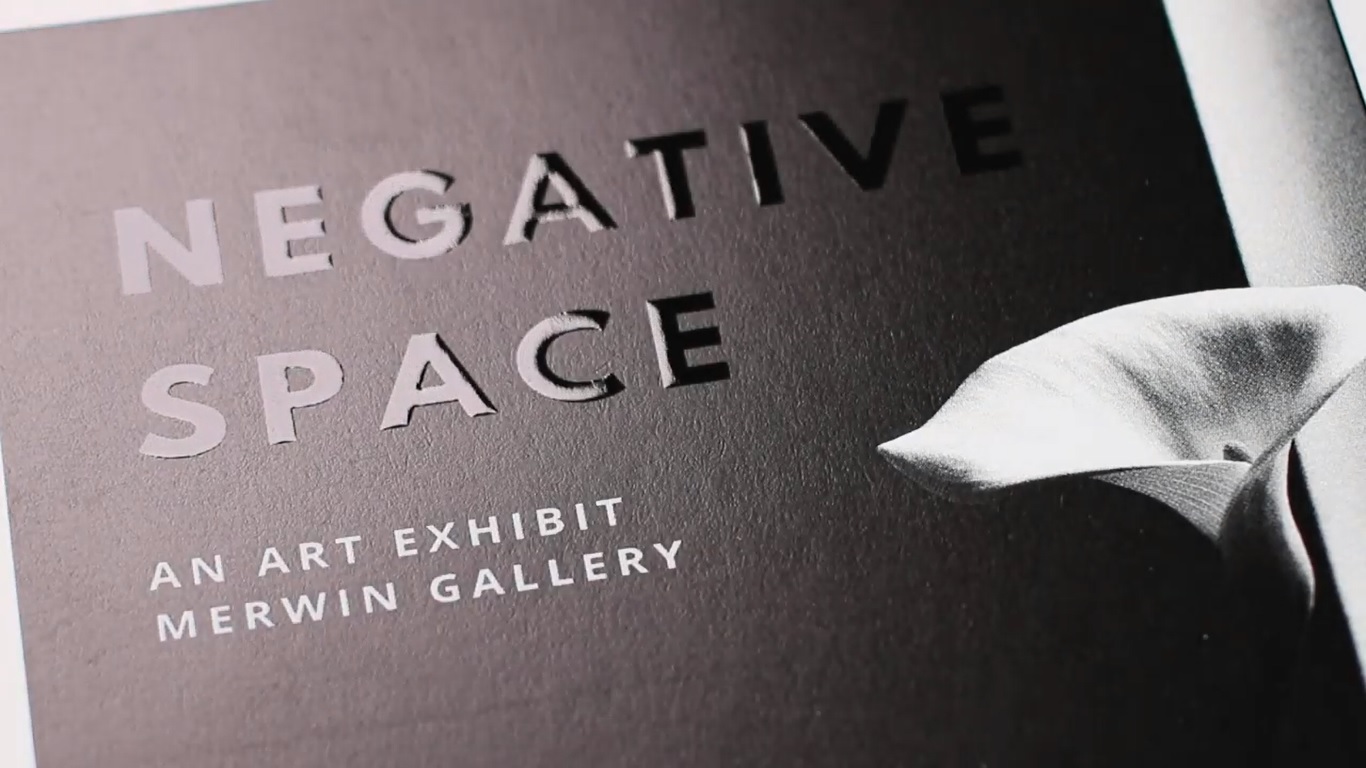

A spot UV is a specific coating technique that includes high-gloss UV application to a surface or product. It uses ultraviolet or UV to cure the varnish on the printed materials to get a glossy finish to the design element. This technique creates a targeted area to look aesthetically vibrant and shiny.

This technique seals the color and protects the surface from moisture and other things that can scratch or tear the product. It also adds protection to the coating of printed products. Similar to lamination, a spot UV also improves the quality of printed materials.

It helps enhance the key elements that become the product’s identities such as names, images, logos, slogans, and artwork designs. Spot UV printing creates quality packaging to distinguish a product or brand from its counterparts.

How is a Spot UV Used For?

You can discover various uses of a spot UV coating like in postcards, business cards, invitation cards, and card stocks. Many brochures and flyers also use this technique in the making process to create more eye-catching looks. Even packaging boxes apply this coating to strengthen their branding.

This coating technique accommodates several appearances from a glossy to a matte finish. You can still choose between high or light glossy, satin or elegant matte, and even a neutral look. It is versatile and fits thinner and heavy paper stocks instead of very fine papers.

How Does a Spot UV Process Happen?

The client gives a mask file including the instruction regarding the location of the UV coating application. The process usually benefits a silk-green to create a distinct UV coating to the selected area. The mask file must contain a clean and sharp edge with black or white pixels.

Clients should avoid shadows, blurs, and gradients in the mask files. A spot UV printing process works best on fewer areas of materials, particularly for artwork or messages. Too much coating often leads to clutter and scattered over the surface or printed material.

What are the Advantages of a Spot UV?

Spot UV printing offers several advantages. It belongs to an environmentally friendly technique because the curing process does not include any volatile compounds or solvents. It gives a protective layer to the product. Hence, it is not prone to moisture, fingerprints, and smudges.

This coating method offers a fast and effective process with quick drying time to produce précised results. The most important thing is it improves the whole presentation with a fascinating appeal and eye-catching finish that standard coating techniques cannot have.

It creates an impactful impression on anyone who looks at it and adds a more sophisticated touch to the printed product or packaging.

Spot UV printing can help you to create an ideal product or packaging with beautiful and professional looks using a single coating method. It is perfect for bringing the packaging look to the next level.

Morgan Azhari, the owner of PrinterUpdate.net, is a dedicated expert in the field of printers, leveraging a wealth of experience and education to create a platform that passionately shares insights and solutions.

With a goal to enhance the printer user experience, my vision for the website is to provide valuable content, making a positive impact on individuals navigating the complexities of printers.