Printer rollers are parts of the printer made of rubber that play an important role in the feeding of printer paper. They can gather dust from the paper and ink leftovers from printing double-sided sheets over time. To clean printer rollers is very easy. You may clean them with water and a clean cloth. This is very useful to resolve most paper-feeding issues with your printer.

When to Clean Printer Rollers

Streaking

Rollers in a laser printer transfer text from the printer to the paper. When it fails to function correctly, the quality of your prints may degrade. It is likely that the roller is filthy if your printed seems lighter than it should or streaky in certain spots.

Use a soft, microfiber cloth that won't leave dust to clean it. Allowing fluids to touch the transfer roller might harm the machine and prevent it from effectively transferring toner. If you find it splotched with black ink, the transfer roller should be replaced.

Squealing

Squealing indicates that the transfer roller is not correctly positioned or that the clamps that hold it are damaged. To prevent injuring other components, remove the transfer roller from the machine according to the manufacturer's instructions for your printer.

When you push down on the right and left sides of the transfer roller, it should feel flat and springy. If repositioning doesn't work, replace the transfer roller; if the clips are damaged, have a professional repair the printer unit.

Jamming

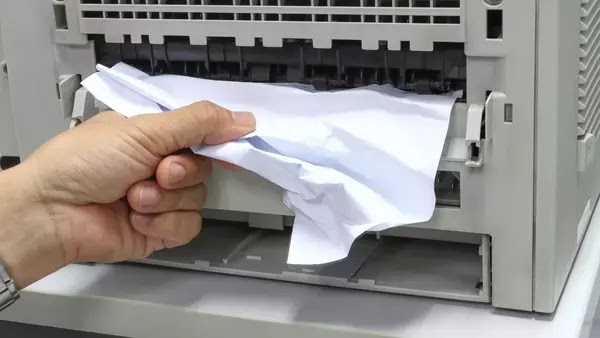

The hardware in the printer may be positioned wrong. If the paper is jammed at the transfer roller. Removing the transfer roller and reinstalling it appropriately can help paper flow smoothly through the printer again. Wear gloves or handle the transfer roller from the ends to keep oils off the unit when removing it. When a new printer arrives, always readjust the transfer rollers since they might shift during shipment.

Odors

If the printer emits an unusual odor, the transfer roller may be filthy or reacting inappropriately with another equipment. In any instance, as soon as you discover the odor, stop all print jobs, remove the printer roller, and then wipe it before returning it in the machine. Print some test files when it's back in place, to see whether it's operating properly.

Cleaning Inkjet Printer Rollers

First and foremost, locate the printer rollers. Printer rollers are commonly found on the underside of inkjet printers. Remove the paper tray and look directly above where the paper tray used to be to discover them.

When you apply pressure to the rollers, they should revolve manually. If not, you will need to rotate them using your printer's “feed paper” option. In either case, you should not have to remove them completely for cleaning.

Then, using a lint-free towel and water, clean the rollers. Fill a cup halfway with distilled water and dip your lint-free cloth into it. The fabric should be moist but not drenched. Wipe the surface of the rollers with a moist cloth to remove any debris or dust that has accumulated over time.

Always be careful to thoroughly spin the rollers to clean every portion of the surface area. Before using your printer again, make sure the rollers are totally dry.

You should apply a rubber rejuvenating agent to assist the rubber printer rollers recover some of their natural slickness and glide. Simply wet the end of a Q-tip or cotton swab with the product and softly massage it over the printer rollers' surface. A rubber rejuvenating product should be available at any laptop or office supply store.

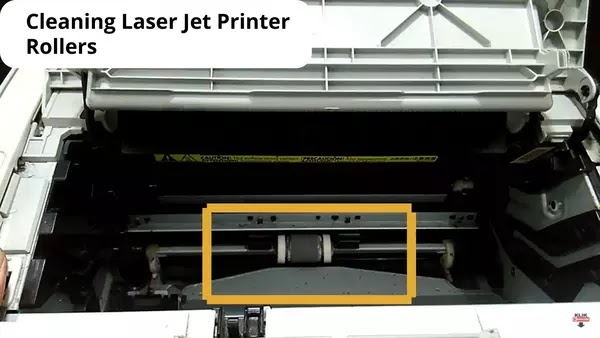

Cleaning Laser Jet Printer Rollers

Some Laser Jet printer rollers cannot be manually rotated. This means you'll need to unclip the clamps on either side of the roller before removing it.

Clean your laser jet printer rollers using an alcohol-soaked cotton swab. Rub it gently over the surface of your printer rollers. Before replacing the rollers in your printer, thoroughly clean and dry them. Check that the cotton swab is just slightly dampened with alcohol and not dripping wet. You don't want too much liquid getting into the laser jet printer.

Dip a lint-free cloth into distilled water and gently clean the surface of your printer rollers to clean any dirt or material that has become stuck. This will assist in cleaning the rollers without drying them out or causing any damage to them. Before replacing the rollers in your printer, make sure they are totally dry.

Remember to check the printer's handbook while cleaning laser jet or ink jet printer rollers. This will inform you which cleaning chemicals are advised as well as any cleaning procedure cautions. If you can't find the printer's manual, call the manufacturer to see what you can do.

What Leads to The Damage of Printer Rollers?

There are several elements that contribute to the deterioration or failure of printer rollers. Some examples are as follows:

Accumulation of Debris and Dust

This is one of the most common causes of printer roller damage. Dust, dirt, toner particles, or paper residue typically collect on the printer's surface over time. If they are not removed, they leave scratches on the surface of the rollers, resulting in printer roller damage.

Near to Self-Consumable Life

Printer rollers are constructed of soft rubber and have a shorter self-consumable life than other printer components. Because they are composed of sensitive materials, they are prone to wear and tear while doing a huge quantity of printing work.

Improper Installation of Printer Rollers

This is another aspect that contributes to printer roller damage. In addition to harming the rollers, poor roller placement degrades print quality. If neglected for an extended length of time, they can potentially harm the printer's other components.

What Happens when Printer Rollers Get Damaged?

Paper Jam

This is one of the most typical issues that can arise when the rollers of printers become broken. This issue can develop in various sections of the printer owing to the failure of various types of rollers. For example, if the paper jam occurs in front of the printer, the printer's feed roller or pickup roller may need to be replaced.

Poor Printing

Poor, unclear, or fading prints might also be attributed to damaged rollers. If your printer routinely produces poor or fuzzy prints, you should inspect all printer rollers and other printer parts as quickly as possible to resolve the issue.

Other signs of bad printing quality include color missing, banding, misalignment, blurry print, and unexpected colors appear in printout. Damaged roller is not always the problem, but it’s always recommended to check it.

Slow Performance

Damaged printer rollers are sometimes the blame for the printer's poor performance. As a result, whenever this problem arises, you should inspect each roller of the printer for any repair or replacement services.

If printer rollers are to blame for any of the aforementioned issues, replacement is the only way to maintain your machine in good operating order. To get the proper printer rollers within your budget, you must choose a reputable and trusted printer store.

Avoiding Future Damage

There are things you can do to avoid possible damage in the future. Of course, the most important thing is to clean the rollers. You should do the cleaning in a proper way so it does not lead to other problems.

Avoid Using Alcohol

First and foremost, avoid over-cleaning rollers using alcohol. When cleaning your printer rollers, do not use alcohol or harsh chemicals. Other types of solvents should be avoided at all costs. These products might cause the rollers to dry out and get fractured and damaged over time. Using these goods may also violate any manufacturer's warranty that you have on your printer.

It is also critical not to overburden your printer. If your printer appears to be having difficulties feeding paper through, spend a few steps to clean the printer rollers. Continue attempting to make the printer function, since this will just aggravate the situation. Regularly maintaining and caring for your printer will give it a significantly longer life expectancy.

Remember to unplug your printer

Before you begin any type of maintenance or cleaning on your printer, be sure it is unplugged. Leaving the printer turned on or plugged in might result in damage to the machine or yourself. You do not want to electrocute yourself or violate the printer's manufacturer's warranty, do you?

Cleaning your printer on a regular basis is an important element of printer maintenance that may improve its efficiency, reduce wasted ink, and give you with better print quality. The higher the quality of paper you choose, the less often you will need to clean the guts of your printer. This is due to the fact that it contains less lint and dust, which can clog the printer. Regardless, dust should be removed from the outside of your printer once a week.

The interior of your printer should be cleaned every six months or 300 hours of operation, whichever comes first. If you use a shared printer in the office, you should clean it once a month. If it is a home printer that is rarely used, it will probably be once every 6 months. However, smearing on the paper while printing something indicates that it needs to be cleaned.

Printer Roller Replacement

New rollers may solve problems and they are an inexpensive place to start. Look for a store which specializes in rollers so you will get the right product. You may buy them in any printer supply stores which provides many kinds of products that match your printer.

Printer rollers, in general, are rubber-based wheel-type components meant to collect paper from paper trays and feed it into printers. These printer rollers become worn or dirty with time, resulting in frequent paper jams and misfeed problems.

As a result, you must purchase replacement printer rollers for your printers. You can get a wide selection of genuine printer rollers to solve your printer problems. Furthermore, you may select from a broad choice of suitable printer rollers for your printer that are developed using cutting-edge technology to meet the demands of printing process applications. So, if you want to save money, go with compatible printer rollers.

You can keep your printer in good operating condition if you clean printer rollers on a regular basis, reviewing the manual, and following these instructions. This will not only guarantee that all of your pages print properly and without streaks or fading, but it will also significantly lengthen the life of your printer.