A printer is a necessary tool for many office tasks. You may use it on a daily basis, but have you ever questioned what printer ink is comprised of? Where does printer ink come from? Today's printer ink is formed of a pigment known as carbon black and other chemicals. Here is the further explanation of the ingredients.

Where Does Printer Ink Come From? Here are the Ingredients

Ink formulations differ slightly based on the manufacturer, the surface that will be printed on, and the printing process employed. Here are some of the most popular materials used to make printer ink.

Pigments

The pigment's primary job is to add color to the ink. Pigments can also give a surface abrasiveness or shine, as well as chemical resistance to heat, light, and solvents. They play an important role in the production of printer ink.

Base pigments are combined with pacifiers and extenders, which are chemicals. These white pigments that induce the ink to become opaque and cover a specific surface, whereas extenders are transparent pigments that make base pigments look less intense. All pigment is crushed up to prevent clumping and to ensure uniform distribution throughout the ink.

Resins

Resins are added to ink to help it bind together into a unique film and to adhere to a printed surface. These materials increase not just the binding of the ink, but also its mechanical qualities. Resins including alkyds, ketones, and acrylics, are also employed in printing to generate glossy or heat, water, and chemical resistant surfaces. Any particular ink will often contain numerous resins.

Dispersants

They are added to assist ink to flow freely and easily transfer to a surface during printing. They stabilize the pigment particles by decreasing the mechanical energy required for grinding. Surfactants and polymers are two types of chemicals that are employed in this attempt and are suspended in a solvent.

Each absorbs pigment particles and produces a covering of varying thickness and composition to keep fine pigment particles from settling. The size of pigment particles affects the intensity of a particular color.

If you are want to know in details, you can read our post about “What is Printer Ink Made Of?“

Performance Additions

Other additives used to impart specific qualities include antioxidants, which delay the beginning of oxidation and function as anti-aging agents, and alkali, which modulates the solubility and viscosity of the ink to prevent it from becoming excessively thick.

Other Ingredients

Many more important elements are added to what printer ink is comprised of to improve its operation. A hygroscopic (water-absorbing) substance, for example, is frequently used to significantly reduce the aging process of ink. A defoamer is another chemical addition that is used to control bubbles and foam efficiency.

Wetting agents are also utilized to regulate the surface qualities of diverse surfaces. Other components include Amine derivatives, which act as pH adjusters. Meanwhile, Biocides are used to suppress the growth of bacteria and fungus.

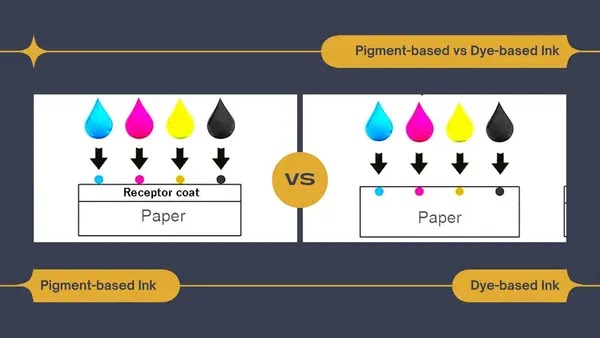

Pigment-based vs Dye-based Ink

Dye-based Printer Ink

It is soluble, which means that it totally dissolves in liquid and changes the chemical structure of its solvent. It is less expensive than pigment-based pigments. This sort of ink produces vibrant colors. It is not, however, waterproof and is prone to smearing. It usually fades after 25 years.

Pigment-based Printer Ink

Pigment-based ink, on the other hand, is insoluble. It requires the assistance of a carrier to dissolve, and particles will be present in the ink. It is frequently pricier. It can print archival-quality photos and text, and it is more resistant to water and UV radiation. It lacks dye-ink brightness and a wide color range, though. Another benefit is that it will not fade for up to 200 years.

The Base Composition of Ink

Color Printing Ink

Color pigments are made up of salts and nitrogen-containing chemicals, sometimes known as dyes. Yellow lake, peacock blue, bluish green, and quick orange are among them. Inorganic pigments are also utilized, albeit they are less prevalent.

These pigments include chrome green, Prussian blue, cadmium yellow, and Molybdate Orange. White pigments, like as titanium dioxide, can be used on their own or to change the properties of specific colored inks. Color printing ink is made by combining these pigments with varnish.

Black Ink

The black ink cartridge will be used in monochrome printers. Carbon black and varnish are used to generate black ink. If the inks are properly formulated, equal quantities of cyan, magenta, and yellow should create a perfect black. However, they are seldom flawless, and the end effect is frequently closer to a slightly tinged gray.

Is Printer Ink Hazardous?

Printer ink is normally non-toxic in tiny amounts and is made in accordance with stringent laws and safety norms. However, it should not be consumed, and ink cartridges should always be kept out of the reach of little children.

If you accidentally swallow printer ink, you may need medical assistance. To determine whether further action is required, review the package or the Safety Data Sheet (SDS). It a thorough document on the hazardous chemical available on the manufacturer's website.

Although a minor amount of ozone and VOC (volatile organic compounds) may be formed during the photocopying process, the EPA investigated the potential detrimental effects of exposure. There were a few incidences of eye discomfort, but none of them resulted in lasting eye damage. Skin irritation incidents were also insignificant.

Always consult an expert if you are concerned if your printer ink is harmful. Although ink poisoning is uncommon, it never hurts to do some study or seek expert assistance to understand more about ink toxicity.

Edible Ink

Inkjet printers can print edible pictures onto sheets of specialized icing papers or rice papers, which can be used to embellish baked items, using edible ink. However, it is preferable to use a clean printer when printing edible graphics to avoid contaminating your meal with prior conventional printing ink.

Proper Printer Ink Cartridges Disposal

|

| source: pinterest |

Printer ink contains various chemical components, such as colors and additives that are manufactured from heavy metals, which may cause major environmental problems. Here are the right methods for handling used and outdated ink cartridges instead of tossing them away.

Recycling Ink Cartridge

Some ink and toner cartridges are made of petroleum and non-biodegradable plastic casing. As a result, instead of tossing away used and outdated ink cartridges, which will eventually harm the soil and water when they reach the landfill, we should properly dispose of them.

Our spent ink cartridges should be recycled. There are several ink and toner recycling programs in our area. In fact, you can earn incentives for recycling cartridges at Staples, Office Depot, and other stores.

Reusing Ink and Toner Cartridges

You can also utilize remanufactured ink and toner cartridges, which are recycled printer cartridges, to lessen the impact of cartridge waste. We could conserve materials, water, and energy that would otherwise be utilized to make totally new cartridges. Remember that there are some distinctions between remanufactured and compatible printer cartridges.

Aside from properly disposing of printer ink cartridges, we must also educate ourselves on how to limit waste from these cartridges. We must acknowledge that there are more methods for practicing green printing, such as duplex printing. We should constantly question oneself, before printing, if the printings are essential. What can I do to practice environmentally friendly printing?

So, where does printer ink come from? All of the ingredients above are combined to make printer ink. This combination might vary based on the manufacturer and the type of ink used. It's mind-boggling to consider how much goes into the production of printer ink.