Are you experiencing printer malfunctions and wondering what might be causing them? One common issue that can lead to such problems is printhead failure. Understanding the common causes of printhead failure can help you troubleshoot and prevent these issues in the future.

Key Takeaways:

- Printhead failure can be triggered by ink clogs, dried ink, dust or lint buildup, lack of airflow, continuous printer operation, infrequent use, and mechanical malfunctions.

- To address ink clogs, manually clean the printhead or use cleaning products designed for printhead maintenance.

- Dried ink can be prevented by running the printer’s self-clean cycle and regularly cleaning the printhead.

- Regularly clean the printhead and ensure proper airflow to prevent dust or lint buildup.

- Turn off the printer regularly to allow the self-clean cycle to run and prevent printhead issues.

Ink Clogs

Ink clogs in the printhead can lead to printhead failure and result in inconsistent printing or even a complete halt in the printing process. When ink thickens or becomes blocked, it restricts the flow of ink onto the paper, causing frustrating printing issues.

To resolve ink clogs and ensure smooth printing, manual cleaning of the printhead is necessary. You can clean the printhead by following the manufacturer’s instructions or using cleaning products specifically designed for printhead maintenance. These cleaning agents effectively eliminate ink clogs, allowing the ink to flow freely and ensuring consistent printing quality.

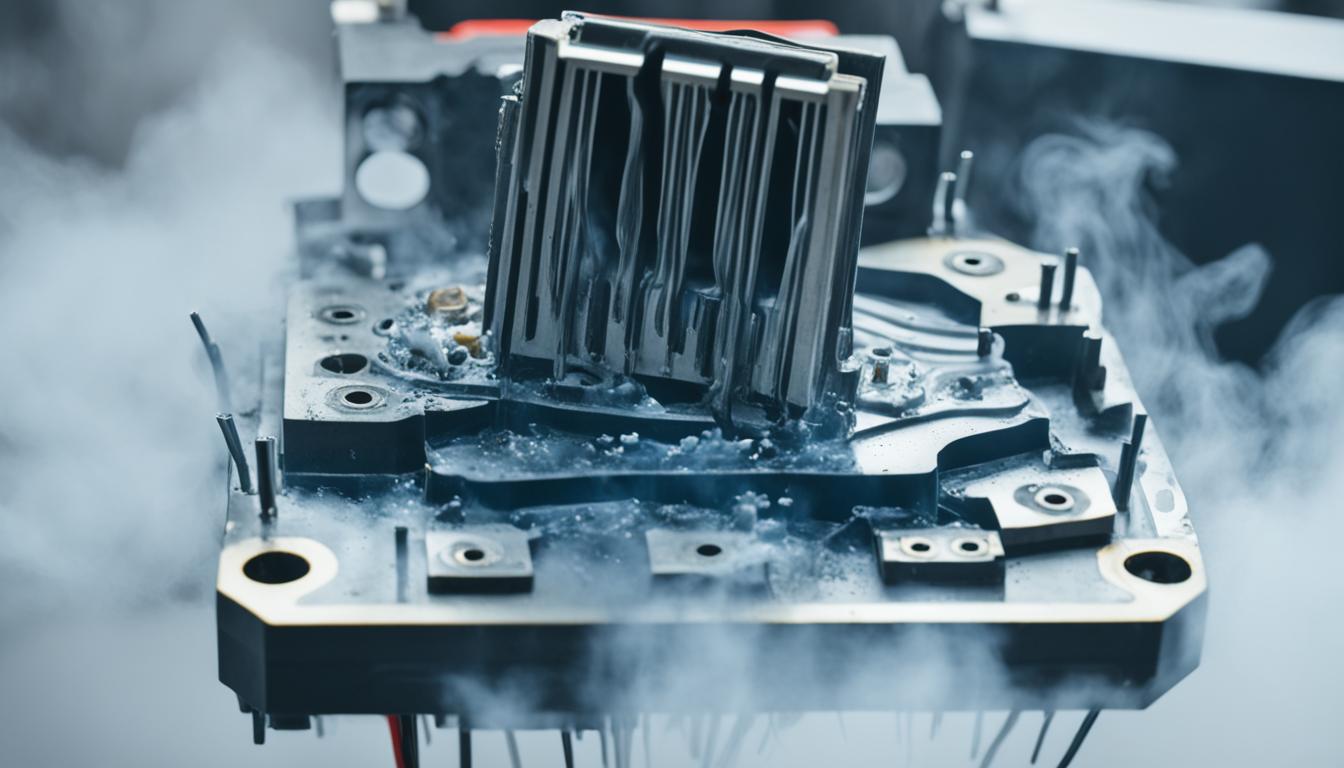

Dried Ink

Ink that remains in the printhead for too long can cause blockages and negatively impact your printing projects. When ink dries up, it forms flakes that can interfere with the smooth flow of ink onto the paper, resulting in ruined prints and unsatisfactory output. To prevent printhead blockages caused by dried ink, it is crucial to implement regular maintenance measures.

If you notice any signs of dried ink or experience printing issues, follow these steps:

- Run the printer’s self-clean cycle: This automated cleaning process helps remove any dried ink particles from the printhead, improving ink flow and preventing blockages.

- Manually clean the printhead: Using a lint-free cloth and an appropriate cleaning solution, gently wipe the printhead to remove any residual dried ink. Be sure to follow the manufacturer’s instructions for proper cleaning techniques.

By performing these maintenance actions, you can effectively address dried ink issues and ensure optimal printing performance. Remember to prioritize regular cleaning and maintenance to prevent future printhead blockages caused by dried ink.

Image: Dried ink can cause printhead blockages and ruin printing projects.

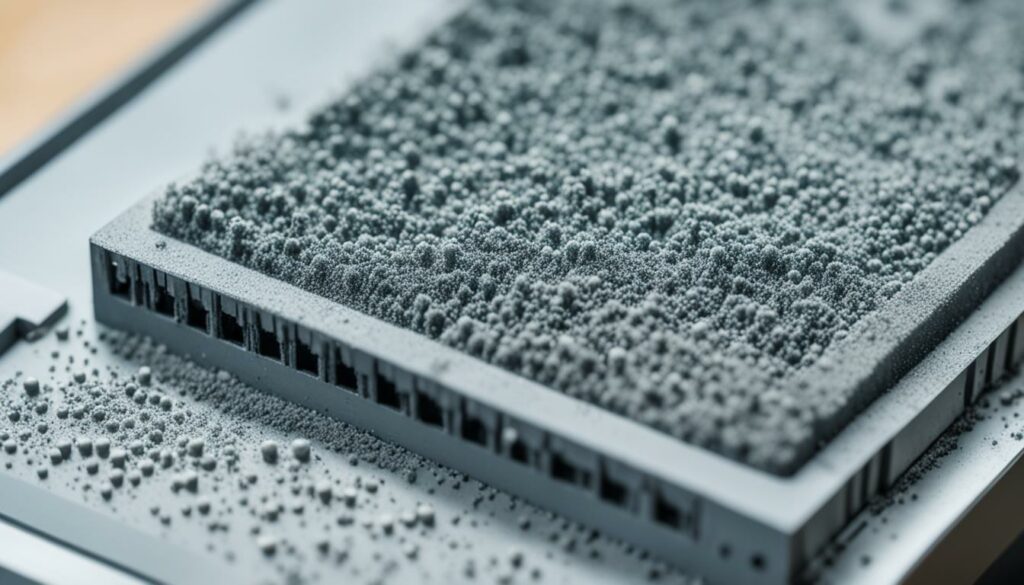

Dust or Lint Buildup

One of the common causes of printhead clogs is the accumulation of dust or lint on or inside the printhead. These tiny particles can obstruct the ink flow and lead to clogs, resulting in poor print quality and inconsistent printing.

The dust particles in the air and lint from garment printing materials are the main culprits for this type of buildup. As the printhead moves back and forth during printing, these particles can get trapped and hinder the smooth movement of ink through the nozzles.

To prevent dust or lint buildup and maintain optimal printing performance, it is essential to regularly clean the printhead. This can be done by following the printer manufacturer’s instructions and using recommended cleaning solutions or cleaning cartridges.

In addition to cleaning the printhead, ensuring proper airflow is crucial. An inadequate airflow can contribute to the accumulation of dust and lint. Keep the printer in a clean and well-ventilated area to minimize the amount of airborne particles that can settle on the printhead.

By taking proactive measures to clean the printhead regularly and maintaining proper airflow, you can significantly reduce the risk of dust or lint buildup and avoid printhead clogs.

Lack of Airflow

Proper airflow is essential for the smooth operation of a printhead. Insufficient or lack of airflow can lead to various issues, including printhead clogs and dried ink. When air nozzles become blocked by dust, lint, or dried ink, it can significantly impact the overall performance and printing quality of the printhead.

To maintain optimal airflow and prevent printhead problems, it’s important to keep the printer in a clean and well-ventilated area. Regularly cleaning the printhead and removing any dust or debris can help ensure proper airflow and minimize the chances of printhead clogs.

Additionally, regular maintenance and upkeep of the printer can help prevent the buildup of dried ink, which can further obstruct airflow. Running the printer’s self-clean cycle or manually cleaning the printhead can help remove any excess ink and maintain a clear pathway for airflow.

“Proper airflow is crucial for preventing printhead clogs and ensuring optimal print quality.” – Print Solutions Magazine

Leaving the Printer On All the Time

One common mistake that users make is leaving their printers on continuously. While it may seem convenient to keep the printer running at all times, this practice can actually contribute to printhead clogs and dried ink issues.

Many printers are designed with a self-clean cycle that automatically runs when the printer is powered on or off. This self-clean cycle helps to prevent ink from drying out and clogging the printhead. However, if the printer is left on all the time, it may not undergo these regular self-cleaning processes.

Without the self-clean cycle functioning properly, the ink inside the printhead can dry out, leading to clogs and poor print quality. The continuous printer operation can also result in the accumulation of dust and debris, further hindering the performance of the printhead.

To ensure proper printhead maintenance and prevent issues caused by continuous printer operation, it is advisable to turn off the printer at the end of each workday. This allows the self-clean cycle to initiate and keep the printhead free from clogs and dried ink.

Key Takeaways:

- Leaving the printer on continuously can lead to printhead clogs and dried ink issues.

- Most printers have a self-clean cycle that runs when the printer is turned off or on.

- Continuous printer operation can result in the accumulation of dust and debris, further hindering printhead performance.

- Turning off the printer at the end of each workday allows the self-clean cycle to initiate and maintain printhead cleanliness.

Next, we will discuss the impact of infrequent printer use on printhead performance and how to prevent printhead failure.

Infrequent Use

If a printer is rarely used, it can lead to various issues, including printhead failure. The sporadic printing allows dust and lint to accumulate in the printer, which can result in printhead clogs and reduced printing quality. Additionally, dried ink can cause blockages and further contribute to printhead failure.

To prevent these problems, it is essential to maintain regular printhead maintenance and ink flow. Even printing something small each day, such as a test sample, can help keep the printhead functioning properly. This practice ensures that ink circulates through the printer, minimizing the risk of clogs and other printhead-related issues.

Quote: “Consistent printing is key to prevent printhead failure. By printing regularly, you can avoid dust and lint buildup and ensure optimal printer performance.”

Regular printing not only helps prevent printhead failure but also enables you to spot and resolve minor issues before they escalate. It allows you to identify any emerging problems, such as printhead clogs or ink blockages, early on, reducing the risk of larger malfunctions and extending the lifespan of your printer.

By incorporating a daily printing routine into your workflow, you not only maintain the printer but also ensure the print quality remains consistent. This proactive approach minimizes the risk of printhead failure and the need for costly repairs or replacements.

Tips to Prevent Printhead Failure in Case of Infrequent Use:

- Print something each day, even a small test sample.

- Ensure the printer is properly shut down after each use to initiate the self-cleaning process.

- Perform regular manual printhead cleanings to remove any dust, lint, or dried ink.

- Invest in printhead cleaning products to maintain optimal printhead performance.

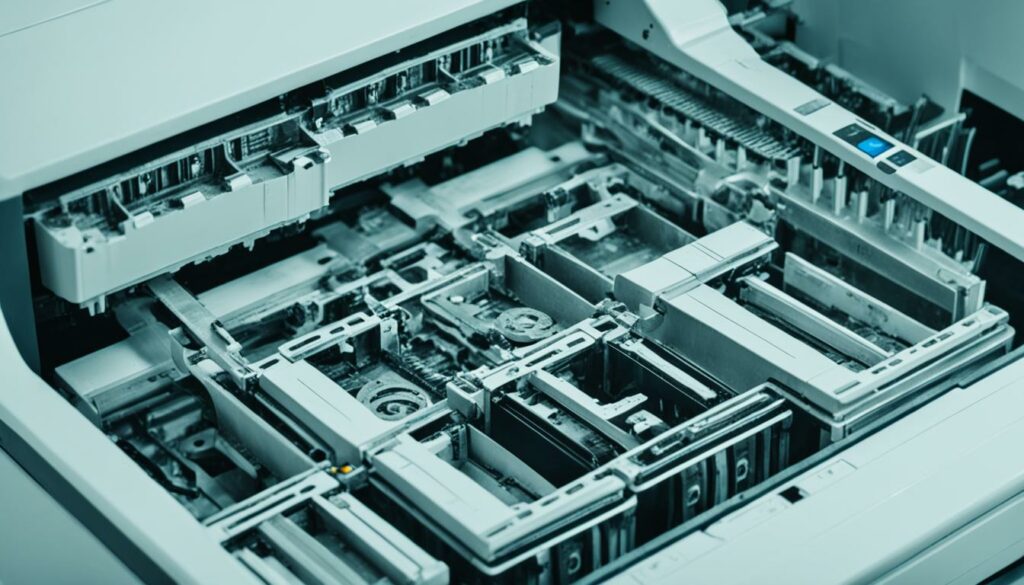

Mechanical Malfunctions

Sometimes, the failure of the printhead can be attributed to mechanical issues. These malfunctions can occur due to various factors, such as faulty components and wear and tear over time. When mechanical problems arise, repairing or replacing the printhead may be necessary to resolve the issue and restore proper printing functionality.

| Mechanical Issues | Causes |

|---|---|

| Faulty components | Defective parts or electrical connections |

| Wear and tear | Normal usage and aging of the printer |

These mechanical malfunctions can disrupt the movement of the printhead, preventing it from accurately depositing ink on the paper. As a result, print quality may suffer, and in some cases, the printhead may stop functioning altogether.

When faced with mechanical issues causing printhead failure, it is advisable to seek professional printer repair services. Trained technicians can diagnose the problem accurately and recommend the most appropriate repair solution. In some instances, replacing the printhead might be the best course of action.

“Mechanical malfunctions can be frustrating, but they are often an inevitable part of printer usage. Seeking timely repair and maintenance services is crucial to avoid further damage and restore the printer’s performance.”

Addressing mechanical issues promptly can prevent additional damage to the printer and extend its lifespan. Regular maintenance, including cleaning and lubricating the printer’s internal components, can also help minimize the likelihood of encountering mechanical problems that could lead to printhead failure.

Common Mechanical Issues Leading to Printhead Failure

- Defective parts or electrical connections

- Print mechanism misalignment

- Failed motor or belt

- Worn-out gears or rollers

- Jammed paper or foreign objects obstructing the printer’s internal workings

Correcting and Preventing Printhead Issues

Proper maintenance is key to resolving printhead problems and preventing printhead failure. By following a few simple steps, you can ensure that your printer’s printhead remains in good condition and delivers optimal printing results.

1. Run the self-clean cycle

Most printers have a self-clean cycle feature that helps remove any ink clogs and keep the printhead functioning smoothly. Running this cycle regularly, as recommended by the printer manufacturer, can effectively resolve minor printhead issues.

2. Perform manual printhead cleanings

In addition to the self-clean cycle, performing manual printhead cleanings can further address stubborn clogs and improve print quality. Refer to your printer’s user manual for specific instructions on how to clean the printhead manually.

3. Utilize the Printhead Doctor machine

If you’re experiencing persistent printhead issues, investing in a Printhead Doctor machine can be a worthwhile solution. This specialized device helps unclog printheads and restore their functionality, saving you time and money on potential repairs or replacements.

4. Regularly use your printer

Leaving your printer idle for extended periods can exacerbate printhead problems. By regularly using your printer, you ensure that ink flows through the printhead more frequently, reducing the risk of dried ink and clogs.

5. Properly shut down your printer

When you’re done using your printer, make sure to shut it down properly. This initiates the self-clean cycle and prevents issues caused by continuous printer operation without regular maintenance.

6. Invest in printhead cleaning products

Using high-quality printhead cleaning products can help prevent printhead failure by maintaining cleanliness and preventing clogs. Consult with your printer manufacturer or trusted retailers to find suitable cleaning products for your specific printer model.

By following these maintenance tips and incorporating them into your regular printer care routine, you can effectively resolve and prevent printhead issues, ensuring consistent and high-quality prints every time.

Conclusion

Printhead failure is a common issue that can disrupt the printing process and lead to inconsistent or ruined printing projects. There are several causes of printhead failure, including ink clogs, dried ink, dust or lint buildup, lack of airflow, continuous printer operation, infrequent use, and mechanical malfunctions.

Fortunately, preventive measures can help avoid printhead failure and maintain optimal printing performance. Regular maintenance is crucial, such as running self-clean cycles and manually cleaning the printhead using proper cleaning products. By taking these preventive actions, you can effectively address ink clogs, dried ink, and dust or lint buildup.

It’s also important to maintain proper printer care to prevent printhead issues. This includes ensuring proper airflow by keeping the printer in a clean and well-ventilated area, turning off the printer at the end of each workday to initiate the self-cleaning process, and using the printer regularly to prevent dust and lint buildup.

By implementing these preventive measures and practicing regular printer maintenance, you can avoid printhead failures and ensure smooth printing operations. Taking care of your printer and printhead will not only save you time and frustration but also extend the lifespan of your printer, resulting in long-term cost savings.

Morgan Azhari, the owner of PrinterUpdate.net, is a dedicated expert in the field of printers, leveraging a wealth of experience and education to create a platform that passionately shares insights and solutions.

With a goal to enhance the printer user experience, my vision for the website is to provide valuable content, making a positive impact on individuals navigating the complexities of printers.