Using a copy machine at the office may seem simple—you just place a document on top and press a button, and you get as many copies as you need.

But behind the scenes, creating that copy involves a complex process. If you're curious about how a copy machine works, here’s a breakdown.

But first, let’s look at the main parts of a copy machine.

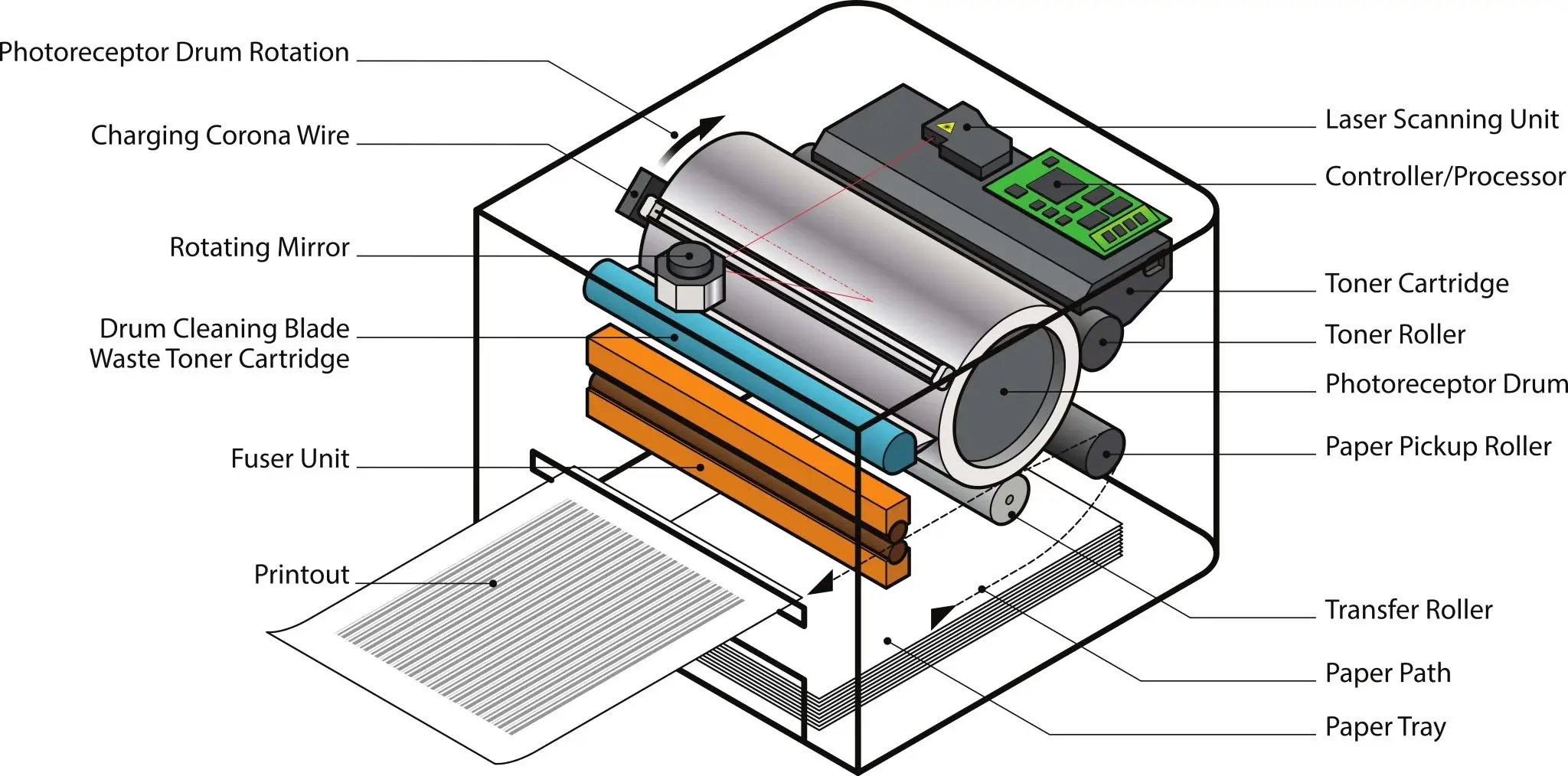

Main Components of a Copy Machine

A copy machine has several important parts, each with its own function. Here are six key components found in most copiers:

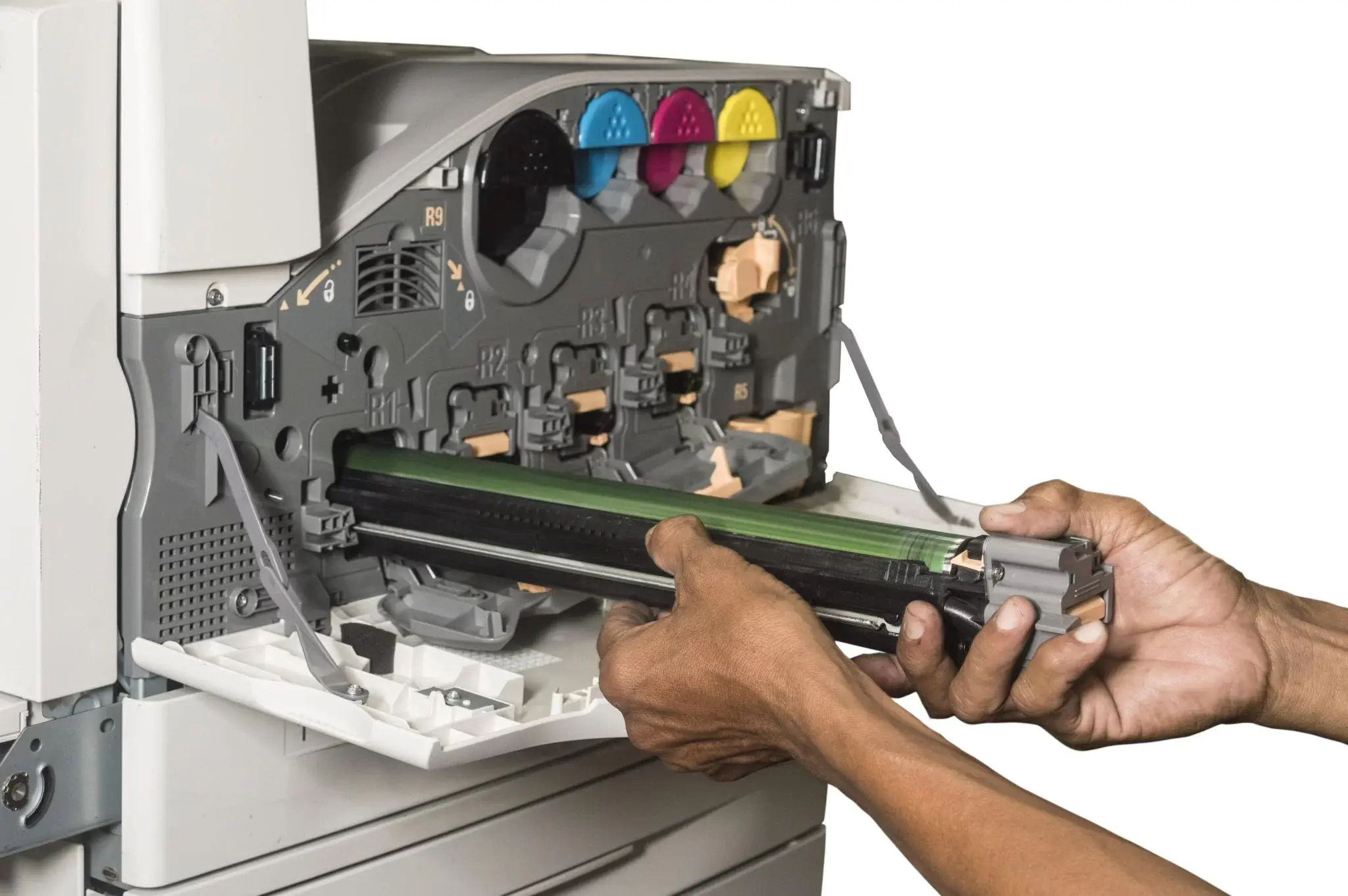

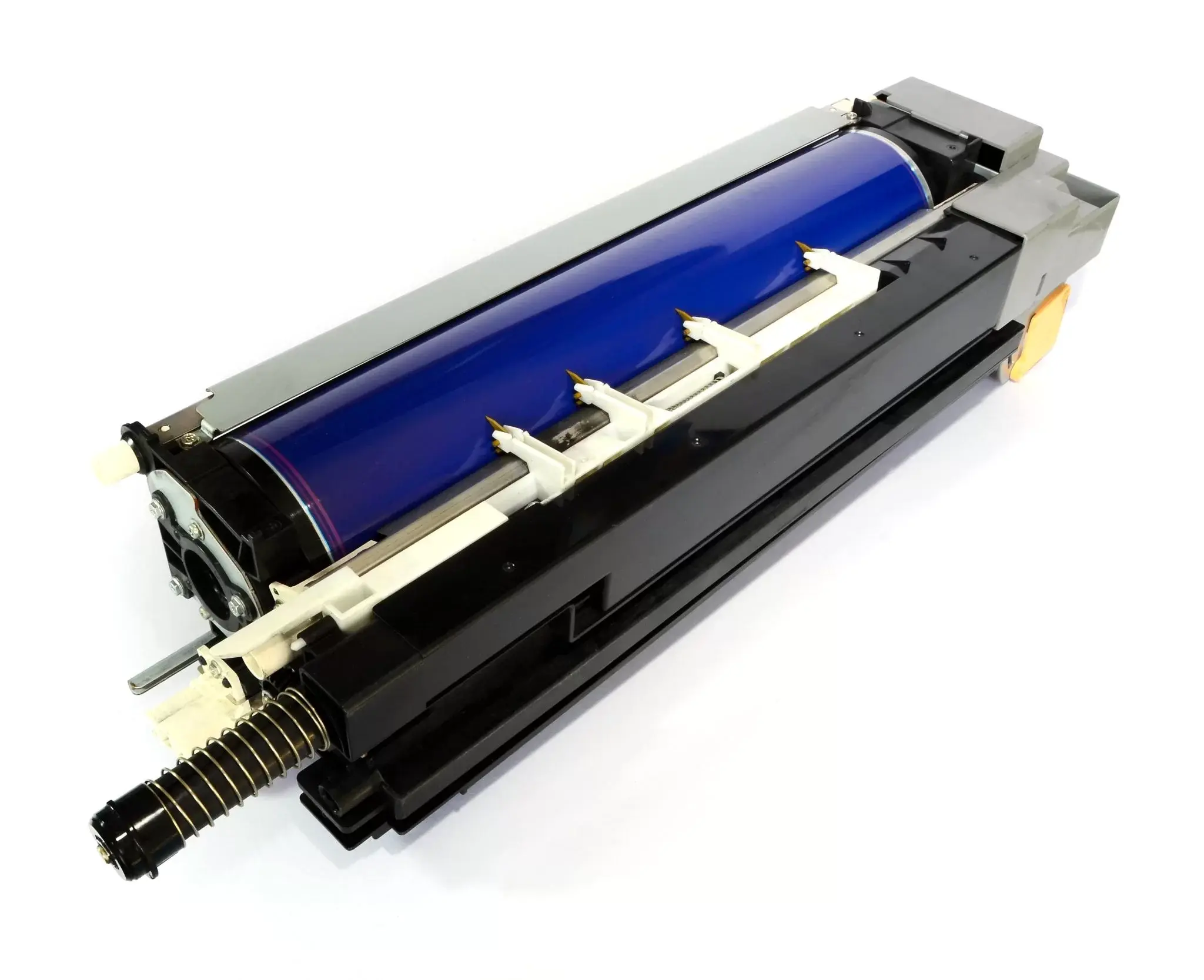

1. Photoreceptor Drum

The drum is a cylindrical aluminum part with a photoconductive layer that’s sensitive to light. It reflects the original document’s image onto the copy paper.

2. Toner

Toner is a colored powder made of plastic resin that’s sensitive to static electricity. It sticks to the photoreceptor drum and turns into ink when heated.

3. Corona Wire

The corona wire is a thin wire that releases electrical charges, attracting toner particles to the drum, which then projects the image onto the paper.

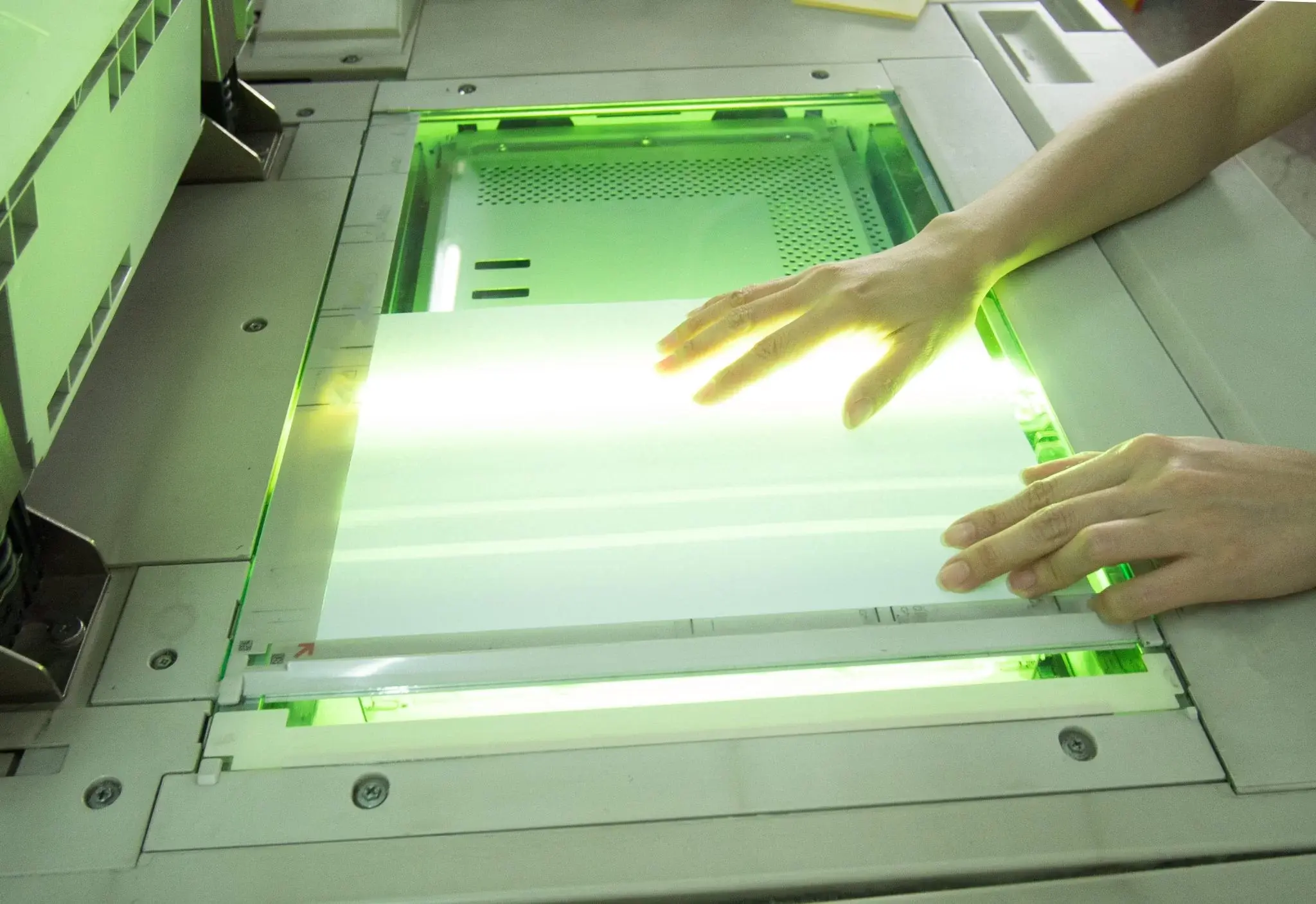

4. Scanner Lamp

This lamp shines ultraviolet light onto the document, sending the image to the lens for copying.

5. Automatic Document Feeder (ADF)

The ADF allows you to copy multiple pages automatically, without having to open the machine each time you want to copy a new document.

6. Fuser

The fuser (or heater) consists of two heated rollers that press the toner onto the paper.

How Does a Copy Machine Work?

In simple terms, a copier works based on electricity and photoconductivity—a process where materials become more conductive when exposed to light.

The copier uses a light-sensitive photoreceptor that attracts toner and transfers it onto the paper to create a copy.

According to Scientific American, Here are the main steps a copier goes through to produce a copy:

1. Charging

The drum is electrically charged to become negatively charged. The photoconductive layer on the drum will conduct electricity when exposed to light.

2. Exposing

The document is scanned with a laser. The white parts of the document reflect light onto the drum and become positively charged, while dark areas (like text) remain negatively charged.

3. Developing

Positively charged toner particles stick to the negatively charged areas on the drum.

4. Transferring

The toner is transferred from the drum to the paper. The paper gets a negative charge to attract the positively charged toner.

5. Fusing

The paper passes through heated rollers, melting the toner so it sticks to the paper. That’s why the paper feels warm when it comes out of the copier.

6. Cleaning

The copier cleans the drum of leftover toner and gets ready for the next copy.

And that’s how it works! Now you know the process and the main parts, making it easier to understand what might go wrong if your copy machine ever breaks down.

I'm Morgan, the creator of VPNForMe — a site born from too many hours spent side-eyeing sketchy VPN reviews and buffering videos.

I wanted a place where people could get straight answers about privacy, streaming access, and which VPNs actually deliver — without the hype or tech jargon.