To attach toner particles to a transfer roller, laser printers employ an electrical charge. When toner particles are pushed into a piece of paper, the laser printer process begins. Meanwhile, the fuser unit's heat and pressure permanently adhere the picture to the paper. The following is a detailed description of how a laser printer works.

The Complete Stages of Laser Printer Process

The process of printing using a laser printer is intricate. There are 7 steps starting from sending the document to making the toner adhere to the paper permanently.

Stage 1: Sending

To start the process of printing, the document is converted into digital data and transmitted from the computer to the printer. The printer reconstructs this computer data into a printed image using binary magic. The data will be captured and processed by the printer.

Stage 2: Cleaning

Laser printers leave a residue on the drum of the printer that needs to be cleaned. Cleaning laser printer is the physical and electrical process of removing the previous print work and preparing the photosensitive drum for the next print job.

Remaining toner on the drum are cleaned using a rubber-cleaning blade into a debris chamber during the cleaning. Electrostatic erase lights inside laser printers dissipate electrical charges left on the drum from previous print jobs. Lubricant is then added to the heat roller to ensure that a suitable quantity of heat is provided uniformly to transfer the incoming picture.

[irp posts=”6192″ ]

Stage 3: Conditioning

Conditioning is the process of providing a charge to the drum unit and the paper as it travels through the corona wire. Adding a static charge to the paper enables for electrostatic transfer of an image to the laser printer page.

The primary charge roller fires up and spins the nearby organic photoconductor (OPC) drum. Static electricity is generated by ions on the corona wire. The electro-photographic process starts at the molecular level. The drum finishes its spin after being coated with a negative charge.

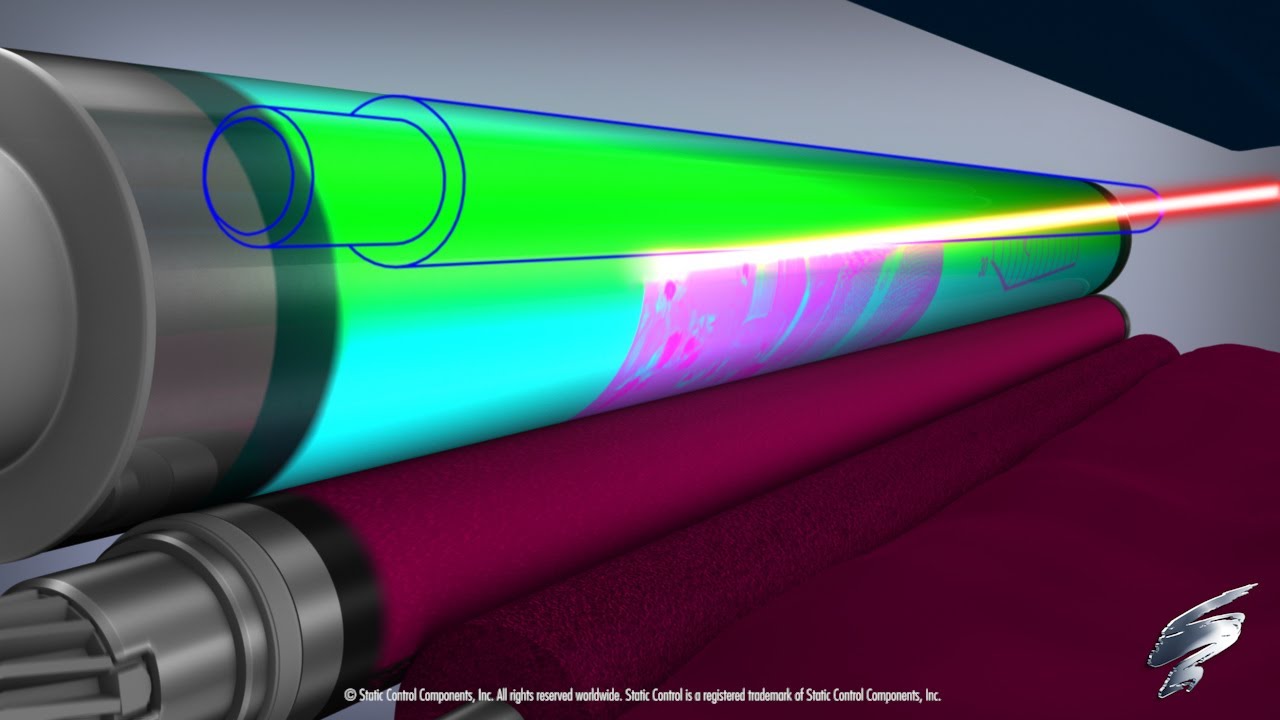

Stage 4: Exposing

The next stage is to expose the photosensitive drum, which involves the use of a laser beam. The surface charge of every section of the drum exposed to the laser is decreased to around 100 volts DC. As the printer's drum rotates, an invisible latent print is produced. For the first time, the picture that will be printed exists as a thin layer of electrons on the OPC drum.

The laser's brightness illuminates the darkness within the printer cartridge. The beam rebounds off a spinning, multi-sided mirror, breaking into many beams of information and showering the OPC drum with knowledge, causing the negative charges to become positive.

The laser connects with the drum unit's spinning surface line-by-line, describing a page in the code of charged toner particles. This includes pieces in black, yellow, and magenta. The drum has a positively charged graphic on its surface that is ready to be printed to paper.

Stage 5: Developing

Toner is added to the latent image on the drum during the developing cycle. Toner is made up of powdered negatively charged polymers like as black, cyan, magenta, and yellow. A control blade keeps the drum at a tiny distance from the toner. Toner is composed of 85-95% finely powdered plastic. Colored pigments, control agents, and fumed silica are other toner materials used in printers.

Silica prevents toner particles from aggregating and adhering to one another. It also aids in the smooth flow of toner from the cartridge to the printer. Control agents like as iron, zinc and chromium are employed to keep the toner particles' negative electrostatic charge. Colored printer toner cartridges are made from a range of pigments.

[irp]

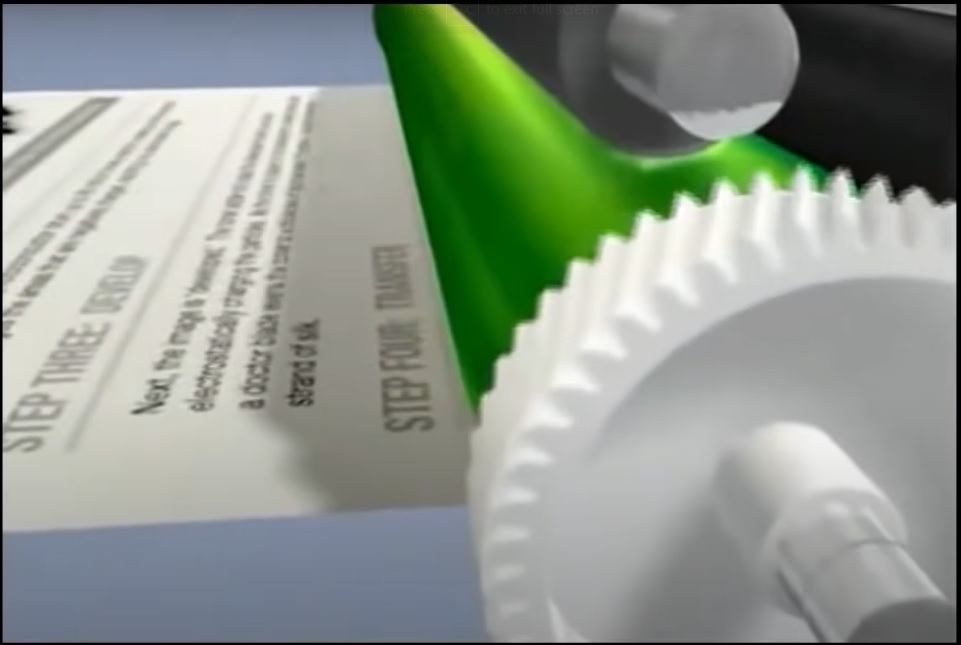

Stage 6: Transferring

The following step is transferring. A positive charge is applied to the paper by the secondary corona wire, also known as the transfer roller. The toner cartridge hopper's agitator unit rotates, and the toner begins to heat up.

The toner adder spins, sucking in toner and collecting dust on its surface. A doctor blade is used to properly level the toner as it moves across the adjacent development roller. Because of all the spinning and turmoil, the magenta particles on its surface have a negative charge, and when they come into touch with the positively charged picture on the OPC drum, the laws of attraction take control.

The negatively charged toner on the drum's surface attracts the positively charged portions of the paper magnetically. According to the laser's precise instructions, magenta toner particles are pulled from the developer onto the drum. A few magenta toner particles here and there, and a slew of others that will mix with black, yellow, and blue to create a rainbow of lovely hues.

Stage 7: Fusing

Fusing is the final stage. Toner is heated and pressed by the fuser device. The toner establishes a lasting bond with the paper when it is pressed and melts into it. The fuser unit is covered with Teflon, and a light silicon oil is added to keep the sheet of paper from adhering to it.

The toner powder is melted onto the sheet by the fuser unit, resulting in the image. A wiper blade removes any remaining particles from the OPC drum and discards them in a rubbish can. The laser printer is ready to perform again when any latent charge on the drum surface is removed, fixed, and refreshed.

Excess toner from the developer unit is cleaned and sent into the hopper for use on the next printed page. Toner from the OPC drum that does not transfer is wiped into a waste toner bin.

Components of Laser Printer

All of components of laser printers have their own role in the printing process. There are 6 main parts of laser printer as the followings.

Drum Unit

A drum unit is a metal cylinder with a specific coating (green in color) that can accept a constant positive and negative electrical charge from a laser printer's laser. The drum is visible in the printer as a green cylinder and is occasionally integrated into the toner cartridge rather than being a separate element.

The corona wire, which is heated during the printer's warm-up procedure, provides the drum with its first static charge. This charge's purpose is to draw positively charged toner onto the drum in order to make a copy or copies of the original document.

Toner Cartridge

A toner cartridge includes colored or carbon / iron oxide powder (toner), which is positively charged before being melted into the paper. Toner Cartridges are consumable items that must be changed in a laser printer after the cartridge is empty. They come in four various colors: black, cyan, magenta, and yellow (CMYK).

[irp posts=”6153″ ]

Electronic Chip

The toner cartridge contains the electrical chip. In some locations, some brands, such as Brother, do not utilize a chip to operate the toner. Essentially, the chip serves as the toner cartridge's brain. It relays any instructions sent to the cartridge in order for it to fulfill its role, such as releasing charged toner powder onto the paper and measuring the remaining toner level. A malfunctioning chip will cause error messages to appear on the printer's LCD screen.

Transfer belt

The transfer belt transports the paper through your printer and over the drum, allowing the toner to be transferred. Some smaller printers lack a transfer belt in favor of rollers that function similarly to a belt.

Laser

The laser component of the printer sends light from the diode through a series of mirrors. They mirror the laser onto the drum unit, embossing the desired print form.

Fuser unit

The fuser unit is a part of the laser printer that is a heated roller that melts the toner particles as they travel through. This seals the toner to the page, making it no longer powdery, and ensures that the toner does not smear or fall off the paper as it comes out of the printer.

Is Laser Printer Suitable for You?

If you print many black and white documents, you should buy in a laser printer.

Inkjet printers are substantially slower than laser printers. Most have high-capacity paper trays, allowing them to print many pages at once. They are also designed to withstand printing hundreds of pages every month without succumbing to wear and strain.

[irp posts=”6195″ ]

Color photographs are not printed as well by laser printers as they are by inkjet printers. They are capable of printing basic images for everyday usage, but they are not designed to print gallery-quality photos. As a result, they're not ideal for photographers or designers.

Laser printers are bulkier and heavier than inkjet printers, making them challenging to accommodate in a home office (even though some models have a more compact size). However, because of their enormous printing capacity, they are ideal for office use.

Once you've determined which sort of printer is ideal for you, you can limit down your options based on variables such as multifunction capabilities and color printing. Your printer is critical to your job or school performance, so choose the finest one for you, whether it's an inkjet or laser printer.

Conclusion

To sum up, the laser printer shoots an outline of your print work on a metal cylinder drum when the computer transmits your print file to it. The drum uses static electricity to extract fine toner powder from its cartridge and then rolls the powder into the paper in the shape of your print outline. As the paper passes through the printer, the heat created by the fuser melts and embeds the toner powder pattern. The final result is ejected by the printer, and the laser printer process is complete.

I'm Morgan, the creator of VPNForMe — a site born from too many hours spent side-eyeing sketchy VPN reviews and buffering videos.

I wanted a place where people could get straight answers about privacy, streaming access, and which VPNs actually deliver — without the hype or tech jargon.