Welcome to our article on DTF (direct-to-film) printing! If you're curious about whether any printer can be used for this innovative printing method, you've come to the right place. In this article, we'll provide you with expert insights and essential information to consider before converting a printer for DTF printing.

DTF printing is a technique where designs are directly transferred onto a film that can then be applied to fabrics or other materials. It offers high-quality prints and opens up new possibilities for creativity in the printing industry. However, not all printers are suitable for DTF printing.

In the following sections, we'll explore the printer requirements, including ink compatibility, temperature control, and media handling, necessary for successful DTF printing. We'll also discuss the process of converting a printer for DTF printing and provide a list of recommended printers known for their compatibility and reliability in this field.

So, if you're interested in exploring DTF printing and want to know which printer is the right fit for this technique, keep reading for valuable insights and tips from our experts.

Key Takeaways:

- Not all printers can be used for DTF printing.

- Printer requirements for DTF printing include ink compatibility, temperature control, and media handling.

- Converting a printer for DTF printing requires technical expertise and modifications.

- There are specific printers recommended for DTF printing.

- Follow the provided tips for successful DTF printing.

Understanding DTF Printing

First, let's understand what DTF printing is. DTF stands for direct-to-film, which is a method of printing where designs are directly transferred onto a film that can then be applied to fabrics or other materials. This process involves using specialized inks and heat to achieve high-quality prints.

DTF printing offers several advantages over traditional printing methods. It allows for intricate designs, vibrant colors, and excellent print quality. The direct transfer onto a film ensures crisp and sharp details, resulting in visually appealing prints that can withstand multiple washes.

“DTF printing provides a versatile solution for businesses in the textile and garment industry. It enables them to create unique and customized designs with ease, enhancing their product offerings and customer satisfaction.” – Sarah Martin, Printing Expert

With DTF printing, you have the freedom to print on various fabrics, including cotton, polyester, blends, and more. This method also opens up possibilities for printing on other materials like leather, wood, and ceramics, allowing for creative applications in different industries.

One of the key benefits of DTF printing is its compatibility with different colors and effects. Whether you want to achieve vibrant gradients, metallic finishes, or neon colors, DTF printing can deliver the desired results, bringing your designs to life.

As with any printing method, it's essential to choose the right equipment and materials for DTF printing. This ensures optimal print quality, durability, and long-term performance. Let's explore the printer requirements and considerations for successful DTF printing in the next section.

Advantages of DTF Printing:

- High-quality prints with fine details

- Vibrant colors and various effects

- Compatibility with different fabrics and materials

- Durable prints that withstand washing

- Customization options for unique designs

Printer Requirements for DTF Printing

Not all printers are suitable for DTF (direct-to-film) printing. To achieve optimal results, certain printer requirements need to be met. These include:

- Ink Compatibility: The printer must be able to handle specific types of inks that are suitable for DTF printing. Pigment-based or eco-solvent inks are commonly used for this purpose, as they adhere well to films and provide vibrant colors.

- Adjustable Temperature Settings: Proper temperature control is crucial in DTF printing to ensure the ink adheres to the film and transfers effectively. The printer should have adjustable temperature settings, allowing you to optimize the printing process for different materials and ink types.

- Compatible Media Handling System: The printer's media handling system plays a significant role in DTF printing. It should be capable of handling films and providing smooth and consistent media feeding. Look for printers with specialized trays or media handling accessories designed for DTF printing.

Meeting these printer requirements is essential for successful DTF printing. Without the right printer capabilities, the print quality may suffer, and the transfer process may not be efficient.

The Importance of Ink Compatibility

One of the key printer requirements for DTF printing is ink compatibility. Using the right ink is crucial for achieving vibrant and durable prints. Pigment-based or eco-solvent inks are commonly used in DTF printing because they provide excellent adhesion to films and deliver rich colors that withstand washing and other applications.

“Selecting a printer that can handle the specific inks required for DTF printing will ensure the best results in terms of color quality and longevity.” – Expert Printer Manufacturer

Controlling Temperature for Optimal Results

Proper temperature control is another important aspect of DTF printing. The printer should offer adjustable temperature settings to achieve the optimal heat required for ink transfer. Different films and inks may require varying temperatures for successful printing and vibrant results. Being able to fine-tune the temperature ensures better adhesion and long-lasting prints on various materials.

Media Handling System: Smooth and Consistent Feeding

The media handling system of the printer also plays a critical role in DTF printing. It should be capable of handling films with precision and provide smooth and consistent media feeding. Look for printers with specialized trays or accessories designed for use with DTF films. These features help minimize the risk of misfeeds or damage to the film during the printing process.

By ensuring that your printer meets these requirements, you can enhance your DTF printing capabilities and achieve high-quality, vibrant prints on a variety of materials.

Ink Compatibility for DTF Printing

When it comes to DTF printing, ink compatibility plays a crucial role in achieving outstanding results. DTF printing requires inks that can adhere well to films and deliver vibrant colors, bringing your designs to life. Two commonly used ink types for DTF printing are pigment-based and eco-solvent inks.

Pigment-based inks are known for their durability and resistance to fading. They provide excellent color saturation and are suitable for a wide range of applications, including textiles and apparel.

Eco-solvent inks are solvent-based inks that are designed to adhere well to films and offer high-quality prints. These inks are known for their versatility and compatibility with various materials, making them a popular choice for DTF printing.

When choosing a printer for DTF printing, it's essential to ensure that it can accommodate these ink types. Check the printer's specifications or consult with the manufacturer to verify ink compatibility, as using the wrong type of ink can result in poor print quality or damage to the printer.

Temperature Control for DTF Printing

In the world of DTF printing, temperature control plays a vital role in achieving optimal results. The right temperature ensures that the ink adheres to the film and transfers smoothly onto the desired material. When considering a printer for DTF printing, it's important to evaluate its temperature control capabilities.

Some printers come equipped with adjustable temperature settings, allowing you to customize the printing process according to the specific needs of different materials and ink types. This flexibility enables you to optimize the heat transfer for vibrant and durable prints.

By precisely controlling the temperature, you can prevent issues such as incomplete transfer, color bleeding, or poor adhesion. It's worth noting that different films and inks may require different temperature ranges for optimal performance. Having a printer with adjustable temperature settings provides the versatility needed to explore various materials and ink combinations.

To ensure successful DTF printing, consider the following:

- Familiarize yourself with the recommended temperature settings: Consult the user manual or manufacturer's guidelines to understand the recommended temperature range for your specific printer model. This information will serve as a starting point for your printing experiments.

- Perform test prints: Before embarking on full-scale production, run test prints using different temperature settings. This trial-and-error approach will help you identify the optimal temperature range that delivers the best results for your printing requirements.

- Monitor and adjust temperature throughout the printing process: For long print runs, it's crucial to monitor the temperature consistently. Factors such as ambient temperature can affect the printer's heat distribution, necessitating occasional adjustments to maintain ideal conditions.

By paying attention to temperature control in DTF printing, you can achieve outstanding results with vibrant colors, excellent adhesion, and durable prints that are sure to impress. Take advantage of printers with adjustable temperature settings to unlock the full potential of your DTF printing endeavors.

“Proper temperature control is the key to unlocking the true potential of DTF printing. It allows for precise ink adhesion and vibrant color transfer, resulting in high-quality prints that will captivate your audience.”

– Anna Thompson, DTF Printing Expert

Comparison of Temperature Control Features in Selected Printers

| Printer Model | Temperature Control | Adjustable Temperature Range |

|---|---|---|

| Epson SureColor P800 | Advanced Temperature Control System | 20°C – 40°C |

| Canon imagePROGRAF PRO-1000 | Precision Temperature Control | 15°C – 45°C |

| HP DesignJet Z9+ | Intelligent Temperature Management | 25°C – 50°C |

| Brother GTX Pro | Digital Temperature Adjustment | 10°C – 55°C |

It's essential to choose a printer that offers precise and adjustable temperature control to meet your specific DTF printing requirements. The table above provides a comparison of temperature control features in selected printers commonly used for DTF printing. Consider these options when seeking a printer that can deliver the desired temperature control capabilities for your projects.

Media Handling System for DTF Printing

In the world of DTF printing, the media handling system of your printer is a crucial factor in achieving successful results. This system determines how well your printer can handle films and ensure smooth and consistent media feeding.

When selecting a printer for DTF printing, it is important to look for models that come equipped with specialized trays or media handling accessories designed specifically for this purpose. These features are essential in ensuring that the film is properly fed into the printer, preventing any complications during the printing process.

By investing in a printer with a reliable media handling system, you can minimize potential issues such as misalignment or wrinkling of the film, which could result in poor print quality. A well-designed media handling system will ensure that the film remains stable and secure throughout the printing process, allowing for precise and accurate transfers.

To give you a better understanding, here is a comparison table of printers with different media handling systems:

| Printer Model | Media Handling System |

|---|---|

| Epson SureColor P800 | Front fine art paper path and rear manual sheet feeder |

| Mimaki CJV150 | Automatic take-up system for roll-to-roll feeding |

| Roland VersaSTUDIO BN-20 | Integrated front-loading media feed mechanism |

As you can see, each printer offers a different media handling system tailored to meet specific needs. It's important to consider the type of films you plan to use for DTF printing and choose a printer that can effectively handle them.

Remember, the media handling system is an integral part of the DTF printing process, and selecting a printer with a reliable system will contribute to smooth workflow and high-quality prints.

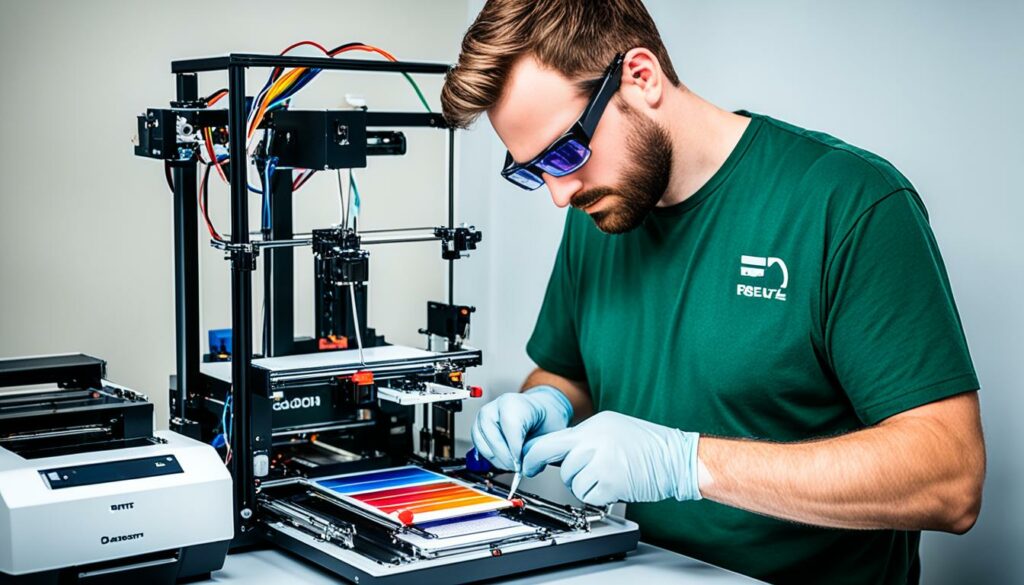

Converting a Printer for DTF Printing

If your printer meets the necessary requirements, you may be able to convert it for DTF printing. However, this process requires technical expertise, as it often involves modifying the printer's firmware or hardware. It's recommended to consult with professionals or seek guidance from experienced DTF printers before attempting any modifications.

When considering converting a printer for DTF printing, it's important to understand the complexities involved. Not all printers are designed to handle the specific demands of DTF printing, and making the necessary modifications requires expertise and a deep understanding of the printer's internal workings.

Modifying a printer for DTF printing typically involves firmware updates and adjustments to the ink delivery system and media handling mechanisms. These modifications ensure that the printer can effectively handle the specialized inks and films used in the DTF printing process.

Attempting to convert a printer without the necessary knowledge and skills can lead to subpar results, damage to the printer, or even complete malfunction. It's crucial to consult with professionals who have specific experience with DTF printing or seek guidance from respected community forums or industry experts.

“Modifying a printer for DTF printing requires technical expertise and a deep understanding of the printer's internal workings.”

By consulting with professionals, you can gain valuable insights into the compatibility of your printer for DTF printing and understand the specific modifications required. Experts can provide guidance on firmware updates, ink delivery system adjustments, and media handling system modifications to ensure optimal performance for DTF printing.

Remember, the success of converting a printer for DTF printing depends on various factors, including the printer model, its internal structure, and the availability of compatible components. It's essential to thoroughly research and understand the risks involved before proceeding with any modifications.

Converting a printer for DTF printing can be a complex process, but with the right knowledge, expertise, and professional guidance, it's possible to achieve excellent results. Before undertaking any modifications, weigh the advantages and disadvantages, and ensure you have a thorough understanding of the printer's compatibility and the modifications required.

Recommended Printers for DTF Printing

When it comes to DTF printing, not all printers are created equal. To achieve optimal results, it's important to invest in a printer that is specifically designed for this application. We've compiled a list of recommended printers renowned for their compatibility and reliability in DTF printing:

| Printer Model | Features |

|---|---|

| Epson SureColor P800 |

|

| Roland TrueVIS SG2-540 |

|

| Mimaki CJV150-130 |

|

These printers have proven to be reliable choices for DTF printing, offering the necessary features and capabilities to ensure exceptional print quality. Whether you're a professional print shop or a DIY enthusiast, investing in one of these recommended printers can significantly enhance your DTF printing experience.

With the right printer, you'll be able to unleash your creativity and produce stunning DTF prints with ease. Remember to always refer to the printer manufacturer's guidelines for optimal settings and maintenance to prolong the lifespan of your printer.

Tips for Successful DTF Printing

To ensure successful DTF prints, it's important to follow some valuable tips and best practices. Paying attention to image preparation, ink settings, temperature control, and troubleshooting common issues can greatly enhance your DTF printing experience. Here are some tips to help you achieve the best possible results:

1. Image Preparation

Before printing, make sure to properly prepare your images for DTF printing. This includes ensuring the resolution is appropriate for the desired print size, converting the image to the correct color mode (CMYK), and optimizing the image for sharpness and clarity.

2. Ink Settings

Experimenting with different ink settings can help you achieve optimal results in your DTF prints. Adjust the ink density and drying time according to the specific film and fabric you're using. It's also advisable to perform test prints and evaluate the color accuracy before committing to a large-scale print job.

3. Temperature Control

Proper temperature control is vital for successful DTF printing. Ensure that your printer's temperature settings are accurately calibrated to match the requirements of the film and ink you're using. Meticulous temperature control ensures optimal ink adhesion and prevents smudging or fading of prints.

4. Troubleshooting Common Issues

Even with careful preparation, issues may occasionally arise during the DTF printing process. Here are some common issues and their possible solutions:

- If the print colors appear dull or faded, adjust the ink density to increase vibrancy.

- If there are streaks or lines across the print, check for clogged printheads and clean them using the appropriate method recommended by your printer manufacturer.

- If the print adherence to the film is inconsistent or peeling off, ensure that the film is properly secured and the temperature is adequately adjusted.

Regularly troubleshooting and resolving these issues can help maintain consistent print quality throughout your DTF printing projects.

By following these tips and implementing the best practices, you can improve your chances of achieving successful DTF prints and creating stunning designs on a variety of materials.

Recommended Ink Settings for DTF Printing

| Ink Type | Recommended Density | Recommended Drying Time |

|---|---|---|

| Pigment-Based Ink | 80% | 15 seconds |

| Eco-Solvent Ink | 60% | 10 seconds |

| Dye-Based Ink | 70% | 12 seconds |

Table: Recommended Ink Settings for DTF Printing

Conclusion

In conclusion, not all printers are suitable for DTF printing. To ensure successful outcomes, it is crucial to consider the specific requirements of ink compatibility, temperature control, and media handling before attempting to convert a printer for this purpose.

If you are unsure or seeking reliable options, it is recommended to opt for printers that are specifically designed or recommended for DTF printing. These printers have been tested and proven to meet the necessary criteria and offer optimal performance.

Additionally, make sure to follow the tips and best practices provided to maximize your chances of achieving successful DTF prints. From image preparation to ink settings and troubleshooting, these tips cover various aspects of the printing process to help you achieve the desired results.

By considering the requirements, utilizing suitable printers, and implementing the recommended practices, you can embark on your DTF printing endeavors with confidence and produce high-quality prints for a wide range of applications.

I'm Morgan, the creator of VPNForMe — a site born from too many hours spent side-eyeing sketchy VPN reviews and buffering videos.

I wanted a place where people could get straight answers about privacy, streaming access, and which VPNs actually deliver — without the hype or tech jargon.